The textiles that are processed in laundries originate from a human community: hospitals, hotels, tourist flats, geriatric residences, schools, gyms, restaurants, etc. As it is a reusable item, it must be free of pathogenic micro-organisms when it is washed. This should be a common requirement for all textiles, regardless of their origin.

Taking into account the type of dirt and the infectious load contained in the fibres, a correct management of the linen must ensure the health of the personnel who transport it, as well as the disinfection and elimination of dirt and stains without harming subsequent users, the fabric or the environment.

WHAT HAPPENS TO THE LAUNDRY AFTER WASHING?

Once the linen is clean and disinfected, strict protocols must be followed to avoid re-infection:

- Physical separation of spaces into clean and dirty areas.

- Collection and handling of garments with personal protective equipment (gloves, gowns, etc.).

- Classification of clothing according to level of soiling, contamination, type of fabric, etc.

- Storage in clean spaces to avoid bacteria remaining in the environment and contaminating clean linen.

- Transporting linen in bags or trolleys and avoiding contact with surfaces as much as possible.

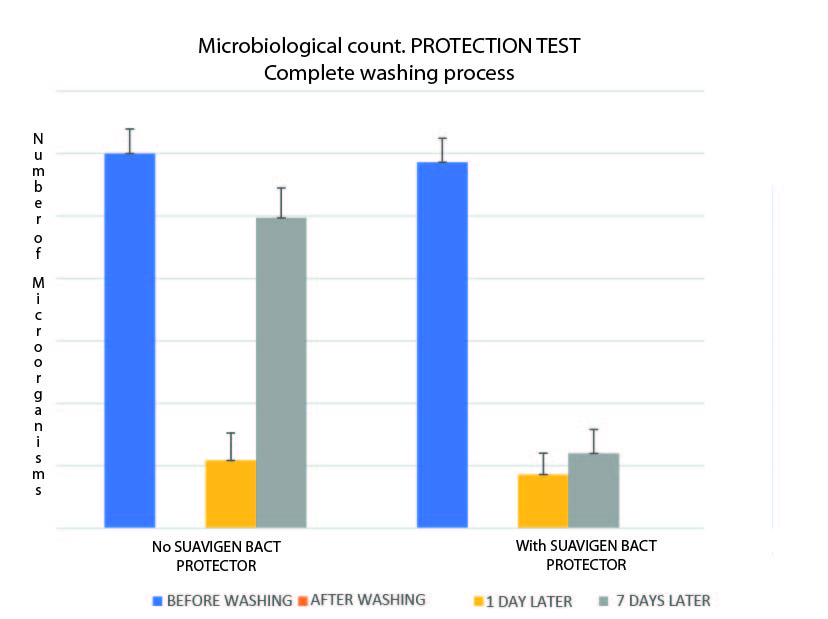

Despite the implementation of these protocols, microbiological tests carried out on different types of garments and fabrics indicate that 100% of the clothes are contaminated after washing, during storage and transport processes.

IS IT POSSIBLE TO PROTECT GARMENTS AFTER WASHING?

Once it has been established that garments are re-infected after the washing process, laundry services must protect the garments to prevent re-infection. Currently the method used is plastic bagging, but it only protects the textiles from possible stains during transport or storage.

For this reason our R+D+i laboratory has developed a new product that achieves a PROTECTOR effect on the fabrics, SUAVIGEN BACT PROTECTOR.

HOW DOES IT WORK AND WHAT ARE THE BENEFITS?

The formula incorporates a very new active material with a fabric protective effect and 100% recyclable that provides an antibacterial treatment to the textile that seeks to prevent the spread of diseases, the bad smell caused by perspiration / humidity or dirt and deterioration of the garments.

The protective active ingredient is present in the product by means of microencapsulation technology which progressively releases it during the softening phase, forming a protective barrier that lasts for at least 7 days.

Contact us if you want to know more.